I’ve been seeing a common question recently – how do I become a better skier? – and I’m immodest enough to think that I have something useful to say on that topic. This is a summary of how I approach skier improvement for adults when I’m teaching.

I guess I should start by defining exactly what I mean by better. It’s one or more of the following:

- Able to ski a wider variety of terrain

- Able to ski a wider variety of conditions

- Able to ski more efficiently – with less effort and/or for a longer period.

Prerequisites

There are a couple of prerequisites that are required for you to learn efficiently, which I call “happy and casual”…

Your happy place

Skiing is inherently a physical skill, and I can’t physically make your body parts move the way that I want to see them move. The best that I can do is try to provide you with opportunities through which you can discover better ways of moving.

To improve the chances of that happening, you need to be able to pay attention to what is going on, process what is going on rationally, and be able to explore modifications to your current technique.

For that to work well, you need to be calm and focused, which I just label as “happy”.

For us to reach that state, we need to feel safe, and it helps a lot of we are also having fun. If you feel scared or distracted, it is very hard to make progress.

Spending a lot of time skiing slopes that are too hard for you is a great way to be in a mental state where it’s hard to improve, and it’s also a great way to develop bad habits.

However, having said all that, you don’t learn to ski bumps on the bunny hill. Part of learning to ski off piste is getting used to skiing off piste so that you can be in that situation and stay in your happy place, or at least not in your very sad place. A little challenge is good as long as you track your mental state and are functioning well in it.

Your casual place

Compare two scenarios. In the first, you are doing a turn every 5 seconds. In the second, you are doing a turn every second.

Which one is easier to analyze and pay attention to?

The first one is obviously much much easier to analyze.

Part of this is terrain choice – choosing a terrain where, at our current ability, we can make turns that are what I would label as “casual”. They’re easy, I don’t have to work very hard, and most importantly, I’m not scared that I’m going to fall.

The second part is about technique; finding ways to modify your technique so that a given terrain becomes more casual for you.

Note that “casual” is about how you feel in a specific situation. Some people are casual on easy intermediates. Some are casual on black diamond bump runs.

Foundations

There are two topics that come up all the time, often enough that I consider them to be foundational. And by foundational, I mean that not addressing issues will limit your ability to improve. Those two things are stance, and turn shape.

Stance

If you ask 10 ski instructors what the most common technique issue for skiers is, 9 out of 10 will say “leaning too far back/not leaning forward enough” (the tenth is daydreaming about skiing). And from that comes the common advice:

- Lean more forward

- Keep your hands up in front of you

- Don’t look down.

Does that work? Well, it can work, but it often doesn’t work great.

It helps to go back to what instructors call “ski/snow interaction”. What are we trying to achieve with ski/snow interaction? WRT stance, it’s two things:

- We want to be able to load (put pressure on) the skis so they will bend and we can therefore use the sidecut to do the turning for us.

- We want to have our weight centered over the skis so that we are going down the slope at the same rate the skis are, so they are not trying to speed up and get away from us.

That boils down to “have enough weight/pressure on the front of the ski so that I can get it to bend and keep up with it”. And the way we exert pressure on the front of the ski is only though the shin pressing on the front of the boot.

Which means there is one bit of anatomy that matters more than the rest: the ankle. If the ankle is flexed and there is pressure on the front of the boot, there is pressure on the front of the ski. If it is not flexed, it doesn’t matter how you are leaning or where your hands are, there isn’t pressure on the front of the boot, there won’t be pressure on the ski.

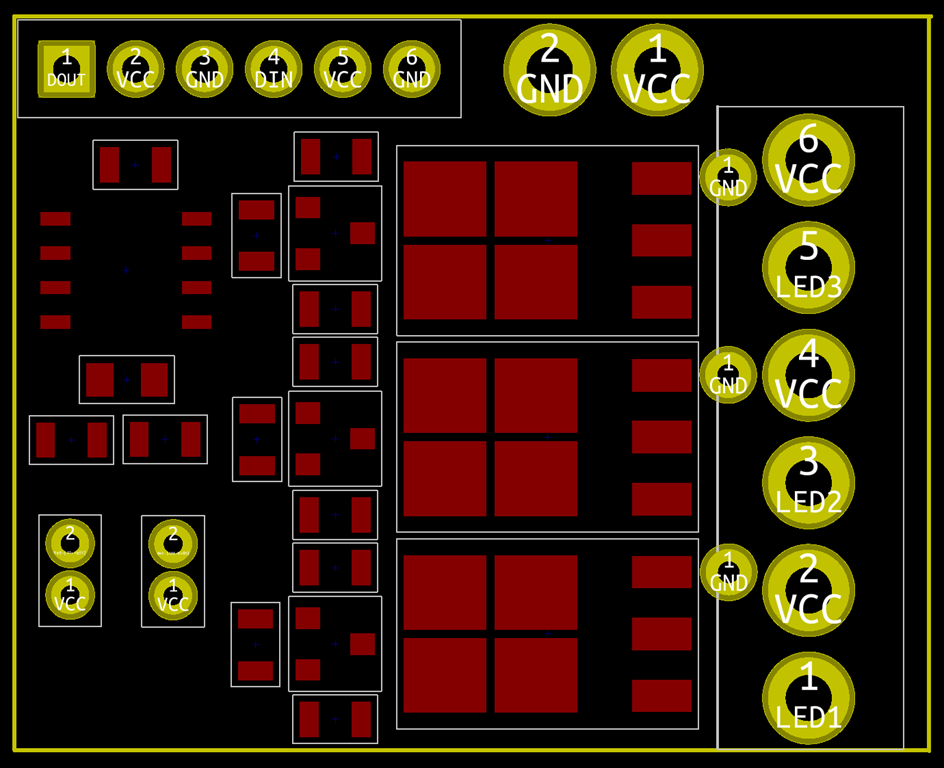

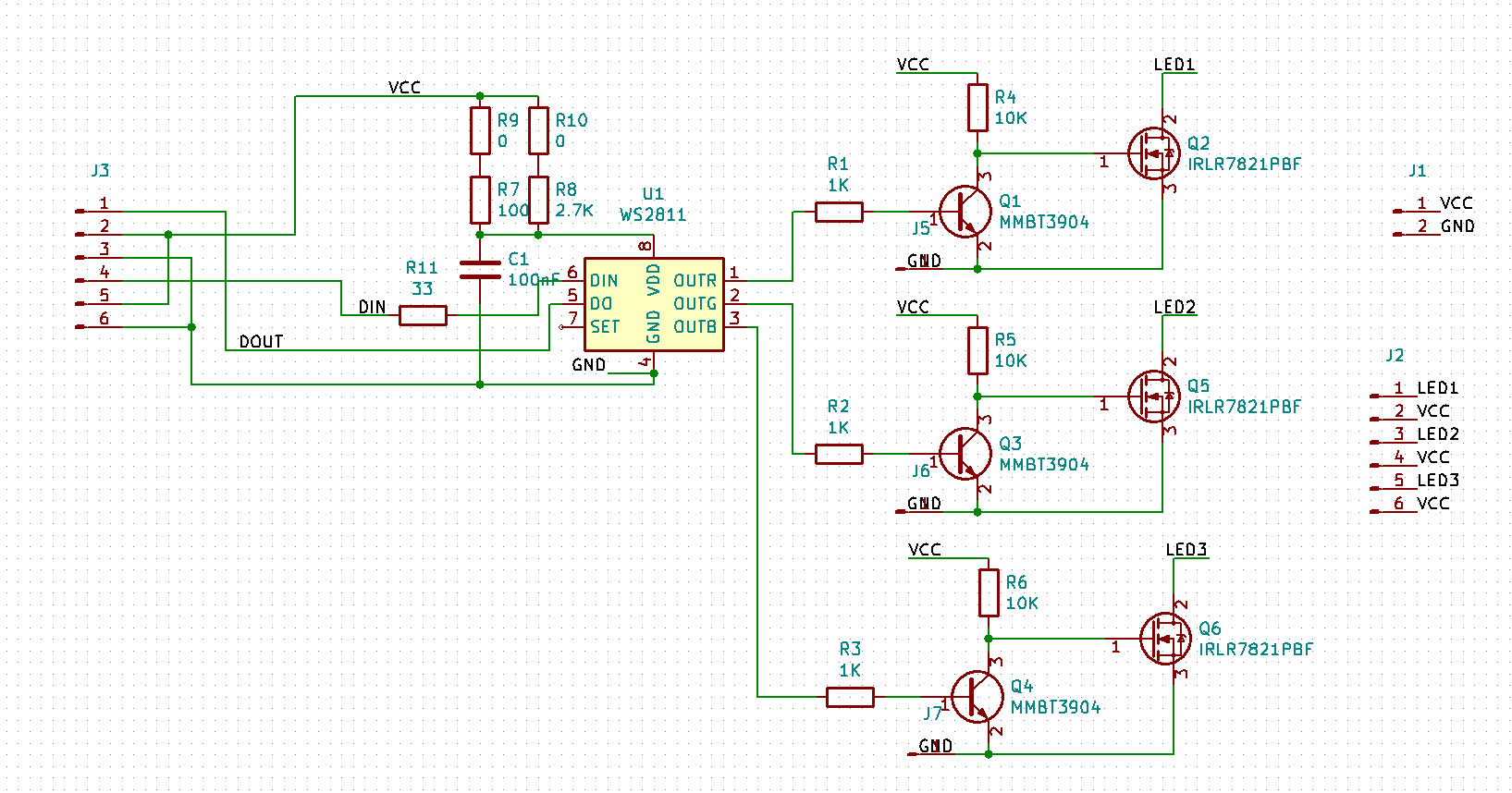

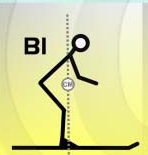

Here’s an example of the kind of stance that I commonly see:

Note how the ankle is loose, but also note that the skier is a) leaning forward and b) has hands in front. Those “lean forward, hands up” cue is not working for this skier.

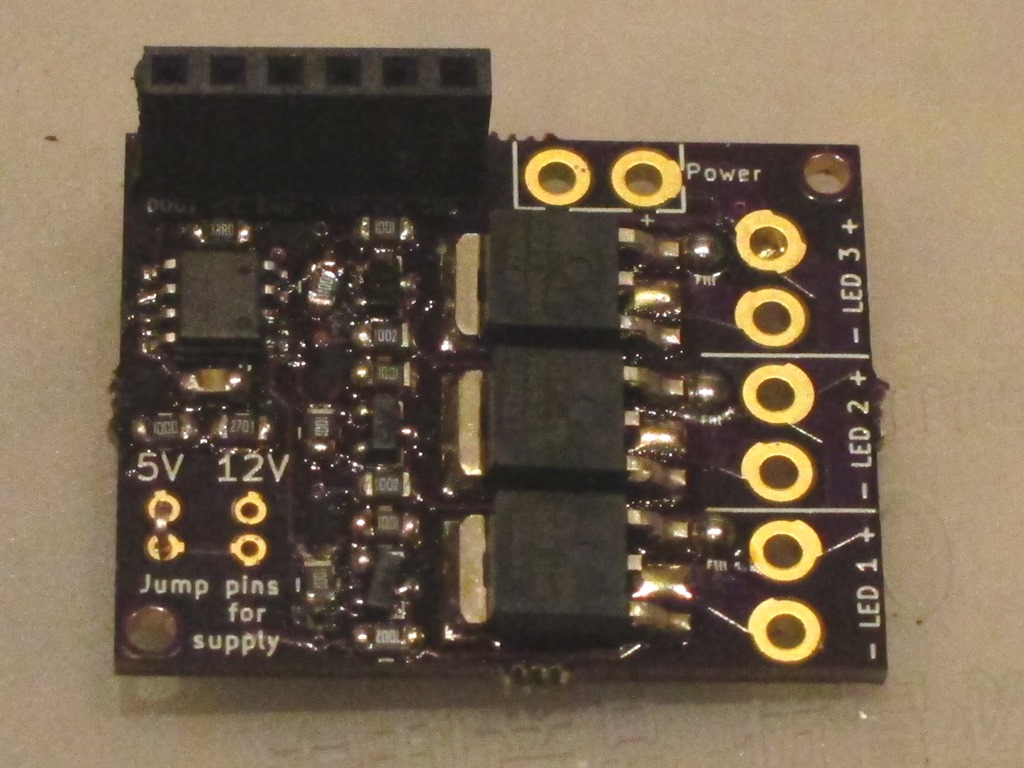

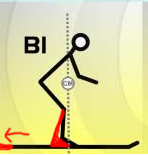

I want that ankle joint to be tighter, something that looks like this:

The ankle joint is tighter – the shin leans forward – but note that the skier is leaning forward less and has hands that are closer to the body.

Looking at the joints in the two images, where are there big changes? The knees have moved forward quite a bit, but the biggest change is in the hips; they have moved forward immensely in the second image. Which leads to my first cue to correct stance; stand up taller and move your hips forward. And also try to keep the angle of your back the same as the angle of your shins.

Not only is this a more functional stance, it’s also a more comfortable stance as it relies more on your skeleton to hold your weight and less on your muscles. Great stuff all around.

That is the stance that I’m searching for.

However, there is something problematic here. Let’s say you are skiing something that is challenging for you to ski and you find yourself in the first position. To get to the preferred, you need to stand up, get your hips forward, and do this while your skis are trying to run away from you. That is generally hard to do because it’s a lot of mass to move, so “stand up and move your hips forward” doesn’t work so great in a dynamic situation.

What is the minimal thing we could do from the first position to get pressure back on the front of the skis? What would be the quickest move? Focus on the ankle…

If we can pull our feet back 5 inches, we can regain the pressure on the front of our skis and get them working properly again, and we can make that move much faster than trying to move our whole body forward. It’s not a perfect stance; it’s still too hunched and is going to burn out your legs faster, but it goes us back to a place where they skis are actually working.

I think that move is foundational in off piste and bumps.

Finding the right stance

Remember the part earlier where I said that my job is to put you in situations where you can discover a better way of moving? The following is what I recommend to so you can discover what the right stance feels like and ingrain it into your neuromuscular connections. It has four steps.

Step 1: Sideslip

In a sideslip, we start with our skis across the hill and roughly equal pressure on both of the skis, and then roll our ankles and knees down the hill until our edges release and we start to slide downhill. Try it facing both directions, and roll your ankles and knees back into the hill to stop.

Here’s a video of what it looks like.

You don’t have to be perfect at sideslip for the purposes of this, but if you have trouble with steps 2 or 3 come back and practice this more.

Step 2: Falling leaf

Start in a sideslip where you are moving straight down the mountain, and slowly shift your weight forward and back on your skis. When you have the weight forward, your sideslip will move sideways down the hill and go forward at the same time. When you have your weight backwards, your skis will go sideways and backwards at the the same time.

Here’s a video of what it looks like. Start by doing it more slowly than the video shows. Pay attention to what your legs and ankles feel like as you are going forward.

Step 3: Diagonal forward sideslip

This is the forward part of the falling leaf held for much longer. Start by going across the hill, and then roll your ankles and knees down the hill slightly to sideslip at the same time. You will need to be in the “forward falling leaf” position for this to work, with ankles flexed and pressure on the front of your boot, and it will feel weird when you first do this. Play around with your stance. Try to stand tall.

It looks like this.

The feeling you get in the forward part of the falling leaf and in the diagonal forward sideslip is the foundation position you want in your stance.

Step 4: Diagonal forward sideslip with turn

Take the diagonal forward sideslip, and add a turn at the end of it. Make sure you are in the sideslip as you start the turn, and then as you exit the turn, get back into the diagonal sideslip. You should find your turns to be much easier.

Turn Shape

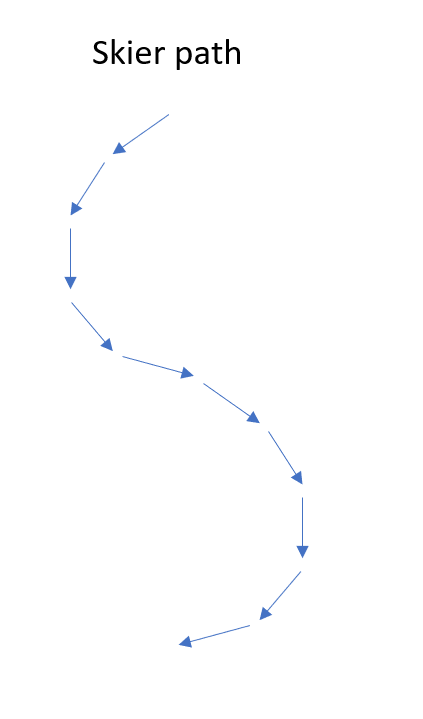

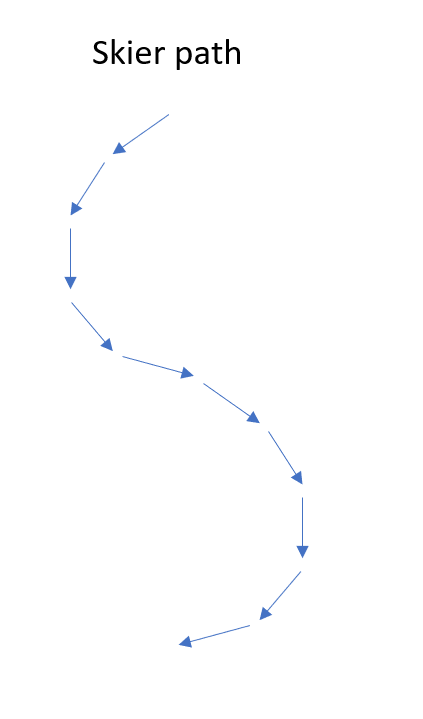

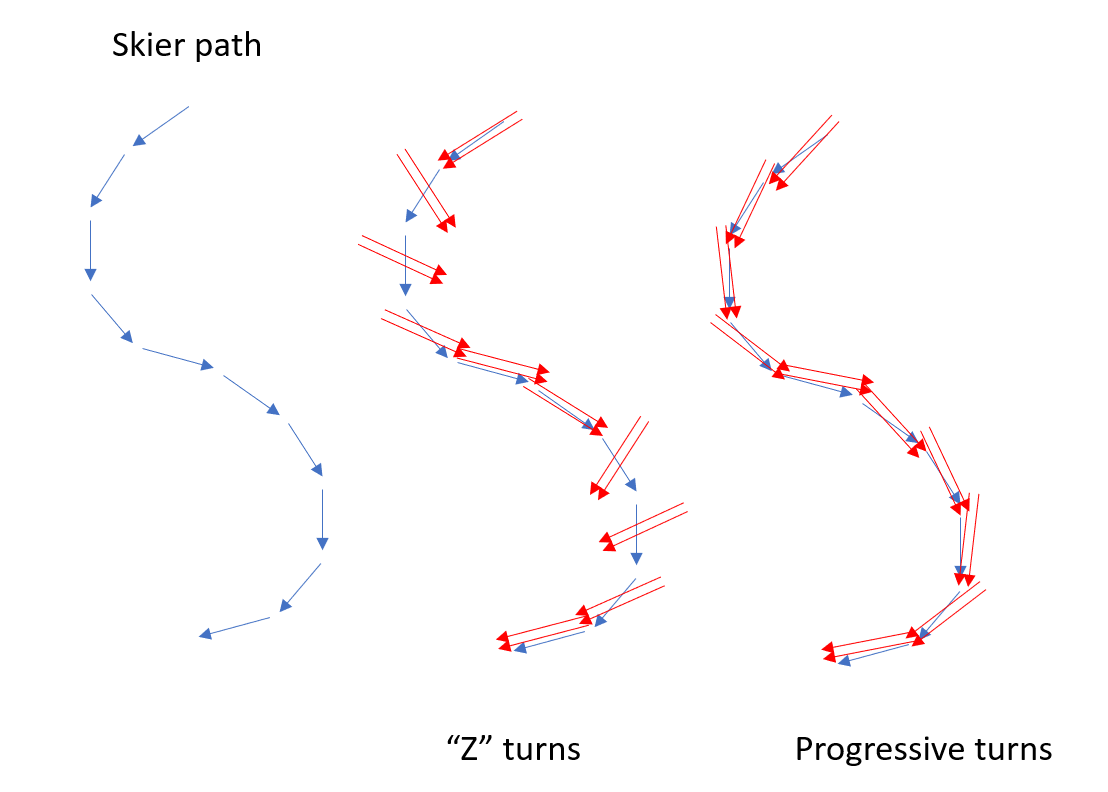

We talk about this foundation as “turn shape”, but I think that is probably the wrong way of looking at it. What we really care about is not the shape of the turn, but the direction that your skis are pointing during the turn compared to the direction that your body is moving. Perhaps a few diagrams will help. Let’s say you are skiing the following path:

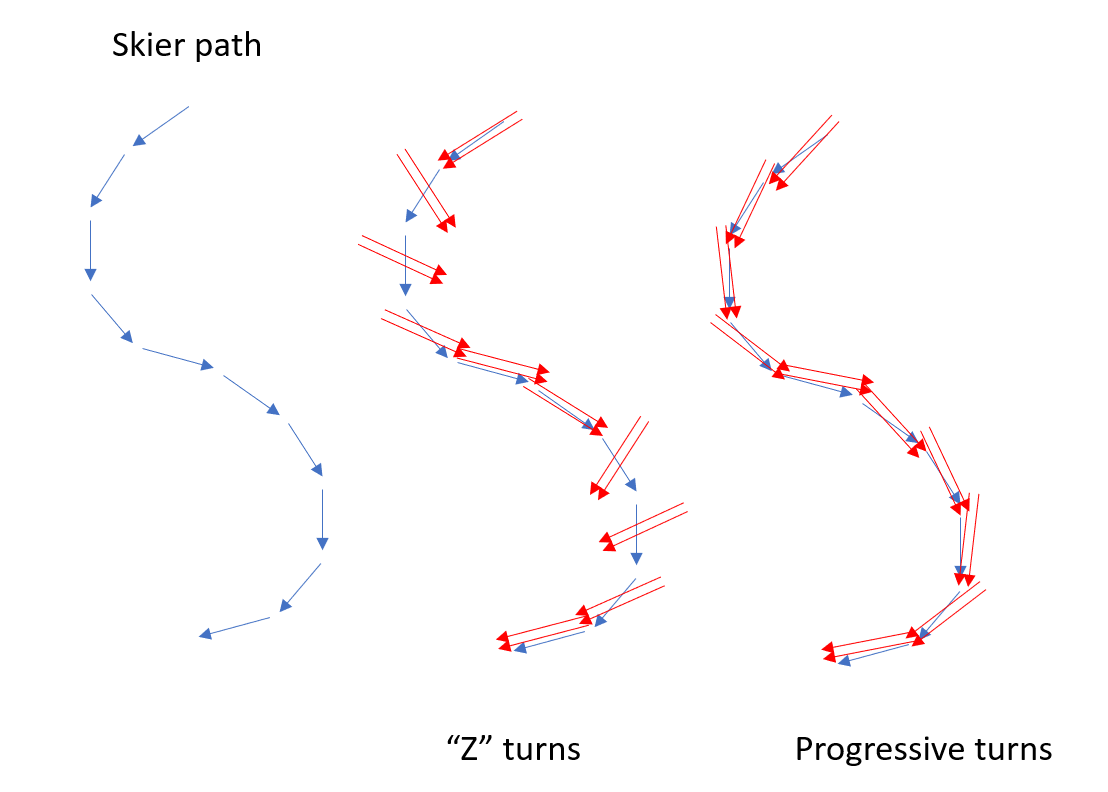

That looks like a nice smooth turning shape. Let’s overlay the direction the skis are pointing in two different turning techniques:

In what we call “Z” turns, at the beginning of the turn, the skis are pivoted quickly across the path of travel and then held relatively straight until the next turn, where they are pivoted quickly across to the other direction. Z turns are problematic because:

- They require big movements and therefore a lot of energy

- Because the turning is quick, they ask more from the condition of the snow; if the snow is scraped off or a icy, they feel much more precarious.

- The motion is so fast that you can’t actually feel what they skis are doing. Remember my part earlier about turns feeling casual so you can focus on what your skis are doing? Z turns make it hard to do that.

In progressive turns, things happen *slowly*, so you can easily tell what is going on.

So, if progressive turns are so much better, why do so many people do Z turns? It’s very simple; if you try to do progressive turns with a rearward stance, your skis take off downhill when they are pointed at the fall line, and you fall over.

My experience is that you can fix your stance, it’s generally fairly straightforward to move towards more progressive turns, but if you want an exercise, I think shuffle turns work pretty well. They are also good because you can’t do them if your stance is too far back.