One of my non-resolutions of late is that I would try to write more – or any – and that I would specifically try to write more humor, because that is the kind of writing I find to be most challenging and therefore most rewarding.

Just to be clear, that’s rewarding to me, not rewarding to you.

Some have complained in the past about my “self deprecating humor”. Putting aside the possibility that it may be the “humor” part they are actually commenting on, I can understand their sentiment, but I have in fact tried to substitute “shelf deprecating humor” (Ikea product names) and “elf deprecating humor” (funny shoes) but have found that to be too limiting. A more specific complaint was that I was using self deprecation because it’s an easy way to get a laugh (duh) and that my depictions were not accurate.

I recently did a bicycle ride that I believe is powerful evidence in my favor…

You can find the official origin story of Sufferin’ Summits here, but suffice it to say that it’s a very hilly ride that was designed to be right on the edge of what I would find possible *given* my aversion to the kind of training that makes rides possible – training every weekend and working your way up to the distance and elevation gain of your target ride.

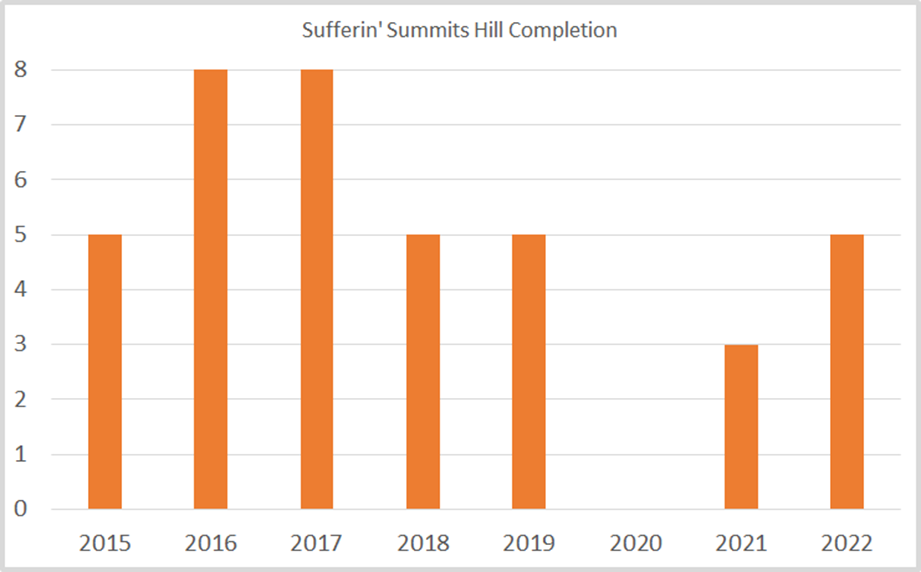

Sufferin’ Summit has 8 designated hills. Here’s a graph of my results by year:

My only true completion was in 2017, though I’m going to count 2016 as I was really close and it was over 100 degrees and I had heatstroke on the last climb. I should also probably note that in 2018 we cut it short because of smoke from forest fires, rain, and an unseasonal plague of locusts.

As you can see, the median is 5 hills, so there’s no self-deprecation when I talk about my performance on this ride – in the last 5 years I’ve been able to finish 5 hills and that’s pretty much the max. Which is, frankly, a bit disappointing for a ride that I created.

Now that I’ve dispatched with the impression that I’m not realistic in my abilities or performance, we can move onto the ride report…

Early in 2023, I read a book about athletic accomplishment and pushing through even if you have difficulties. I don’t recall the title, it was something like, “Okay, it’s broken, but there’s no bone showing…”. And I decided that this year I was going to actually train for Sufferin’ Summits – which means going out and riding the same hills on training rides in the months before the ride and working a bit more on leg strength during my other rides.

And it was all going great until a Thursday night ride on the 20th of July, in which I was riding in the hills – as one does – with a two of my friends, and I noticed that I was cold and 20% short on my usual ration of Vim and Vigor.

The next day I started to feel sick, and that day or the next my wife tested positive for the Covids.

And for once, I don’t have need to invent an excuse for my performance as instead of spending 7 weeks riding hills and improving my fitness for what I hoped would be my second successful completion, I spend 3 weeks coughing and a further 4 weeks estimating the percentage of lung capacity loss I was experiencing when I was trying to exercise.

Which brings us to the Sufferin’ Summits ride. I already decided not to do the Passport2Pain ride – which honestly is a much better ride than mine – but since I host the ride people expect me to show up and if I show up the least I can do is try to ride the first hill (never let it be said I don’t do the least I can do…)

Saturday the 9th turned out to be a nearly perfect day, with a temp around 55 to start and an estimated high of 80. The only better day would be 60 and overcast.

I had very low expectations. The previous Tuesday my riding group climbed the upper part of the first climb – known as Grand Ridge – and I was okay as long as I didn’t work too hard, so I was pretty sure that the title of this writeup would not be “Sufferin’ Summit”. I was hoping to do 2 hills and though that 3 was a stretch since I know the third hill quite well.

The group of 10 or so left the start at a little after 8, and we rode together to the first hill. My legs feel weird – generally spinning easy on the flats they should feel great, but they don’t. Not foreshadowing, just odd. At the bottom of the first hill, two “faster than me” friends pulled ahead and I knew I would not see them again. Which is fine – this is a self-paced ride and “ride your own pace” is explicitly one of the rules.

Grand Ridge was fine. I suffered up the steep parts – there’s one grade that is 18% IIRC – and was really out of breath and it took me at least 30 seconds to recover, which is just a post-covid symptom, but other than that I felt okay. This is a big climb – a little over 1000’ – but it’s frankly not a super difficult climb, even on the route we take. That’s why it’s the first climb on this ride.

A fast descent and we headed over to Squak Mountain. Our route goes up what I would call “the hard way”, and the first section has undulating sections of 10%-16% that took us about 10 minutes to climb. Like the early steep stuff, I got pretty out of breath. This is a bit of a weird climb in that once you past the lower part, there is one steep section and then the rest of the way it’s pretty manageable. We topped out at the water towers at the top, and I felt okay.

Another quick descent and we headed to Talus.

Talus has a perfectly nice entrance to the development, with a good bike lane up to the midpoint, but it’s not the hardest way up, so Sufferin’ Summits goes up an old road that is/was used to access city property. It’s thin and painfully steep, steep enough that even if I ride very slowly it still requires quite a bit of power. I generally deal with it by whining the whole way up, but with my lungs still below par I found myself at what is technically know as the Maximum Voluntary Ventilation – breathing as hard as I could. It’s that feeling you get while you are recovering from a sprint, but I still have another 4 minutes of climbing and I’m enough on the edge that I’m not sure I can clip out of my pedals.

Keep going and maybe pass out or try to stop and probably fall over? I don’t understand why more people don’t show up for this ride.

I did make it to the top, and then there’s after quick flat spot there’s a short section steeper than 20% and a short slog to the top. Of this side of the development. Then it’s over to the other side of the development, to climb another 300’ to the real top of the development.

At the top I took stock in myself and thought about what the next hills were like, and decided that I needed to be done for the day. I could *maybe* have done the fourth hill, but it would have pushed me to the limit of my current fitness and health and was therefore contraindicated in my opinion.

But at least this time I have a real excuse.

If you care for the Strava for the ride, you can find it here.

Stats

Distance: 19.14 miles

Time: 1:48:18

Elevation Gain: 2792’

Time Climbing: 1:12:22

Average Speed: 10.6 mph

If you