My WCS 1994 is having some issues; the DMD display is showing static and now the game is behaving strangely.

I’ve been using the guide here, but I’d like to share some other data I’ve gathered since I didn’t find it elsewhere.

| Test point |

Working DC |

Working AC |

Problem DC |

Problem AC |

Description |

| TP1 |

14.7 |

0.63 |

13.5 |

0.08 |

+12V filtered but not regulated |

| TP2 |

4.93 |

0.01 |

4.97 |

0.001 |

+5V regulated Digital supply |

| TP3 |

11.92 |

0.008 |

0.758 |

0.122 |

+12V regulated digital supply |

| TP4 |

0.37 |

0.63 |

3.62 |

0.06 |

+50V filtered |

| TP5 |

|

|

0.03 |

|

Board ground |

| TP6 |

73.2 |

0.2 – 0.8 |

75.1 |

0.01 |

+50V for solenoids, flippers |

| TP7 |

21.7 |

0.09 |

21.6 |

0.04 |

+20v flash lamps |

| TP8 |

15-17 |

0.2 (ish) |

11-14 |

0.8 (ish) |

+18 to lamp columns |

“Working” values come from my Twilight Zone (working), while “Problem” ones come from my WCS (not working).

What can we tell from this?

Well, a few things. The obvious issue is TP3; it is less than 1 volt when it should be around 12 volts, and it’s letting a lot of AC through at all.

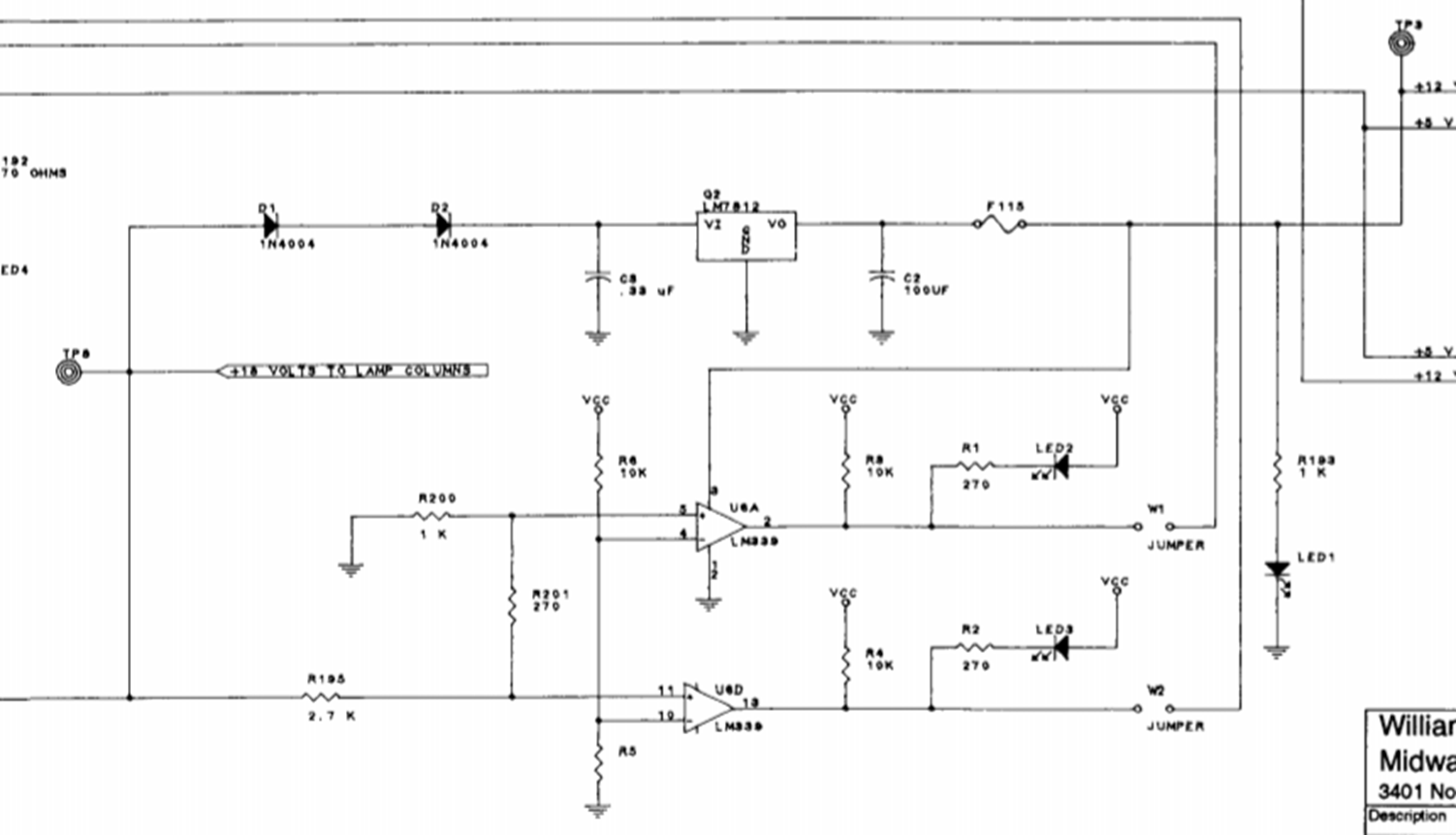

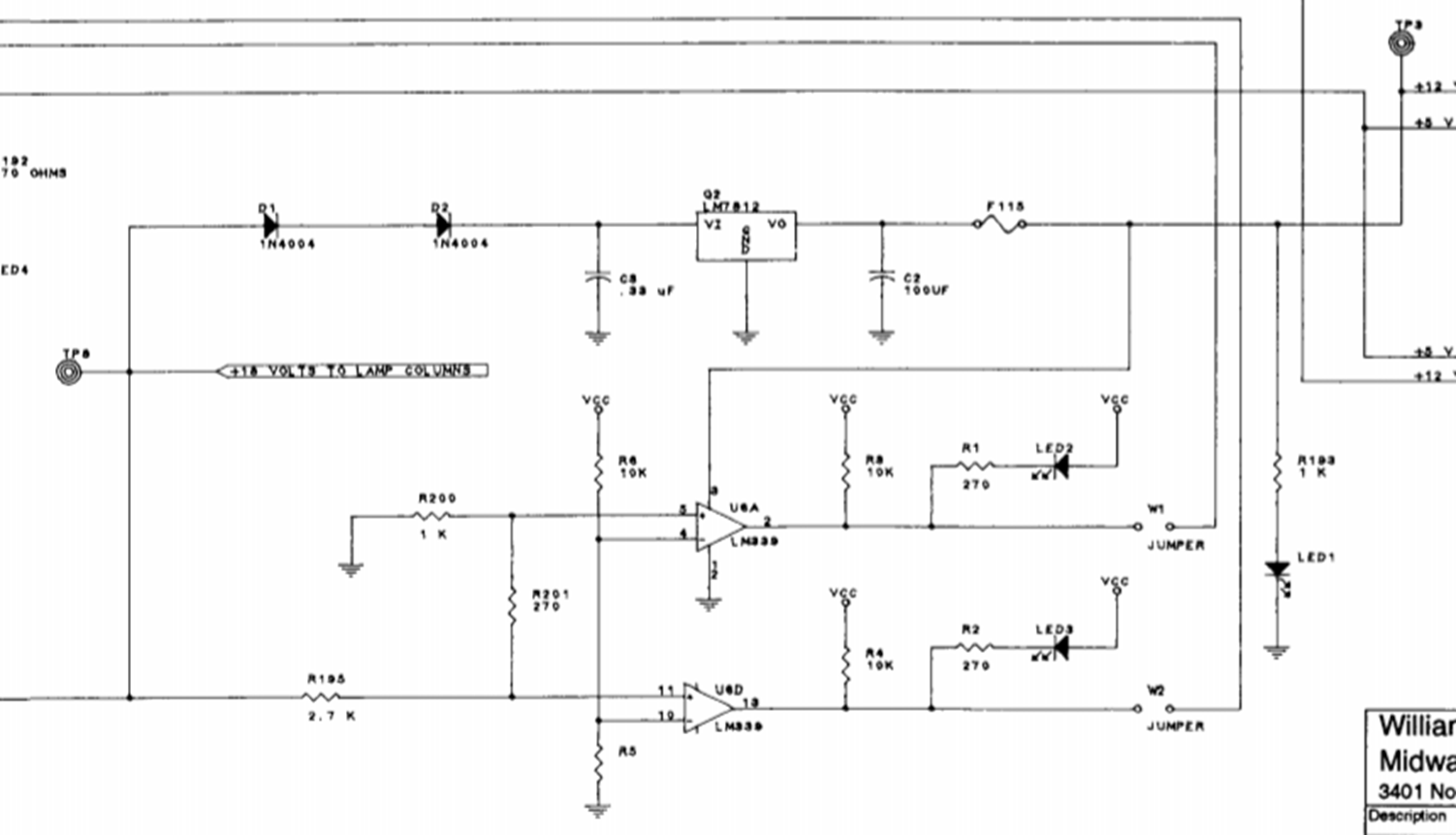

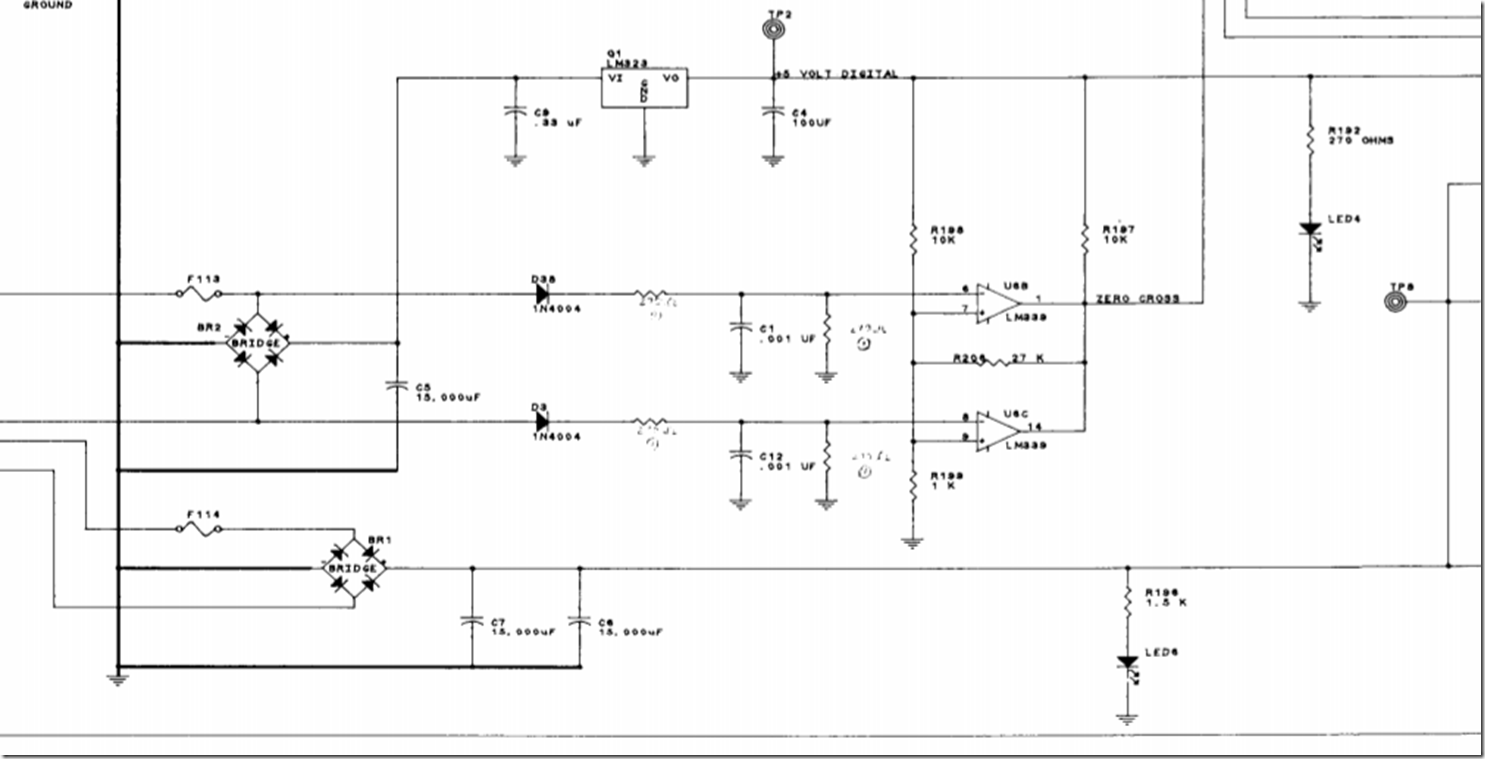

Time to pull out the schematics.

Sorry, that was the best image I could pull from a PDF; the paper version isn’t much better.

Basically, we have power coming in from the left side, which should be a nice healthy 18volts (measured at TP8). It goes through two series diodes that will drop the input by a little over a volt, and then it goes to an absolutely-standard 78xx linear regulator circuit; a capacitor on the input, a 7812 (for 12volts) and a capacitor at the output. 78xx regulators are pretty robust, so let’s see if we’re using it correctly…

Like most linear regulators, the 78xx series has some limitations around input voltage; it requires about 2 volts of headroom to be able to give us the output voltage, so we should be looking for 14 volts coming in. We have 11-14 volts – it fluctuates because the lights are flashing in attract mode. That 11-14 volts isn’t enough to consistently give us enough voltage for the 7812 to give us a nice 12 volts.

So, we don’t have enough power coming in, so that is the problem, right? Well, not so fast. Based on what I know about the 78xx regulators, one would expect that if the voltage drops enough so that you don’t have a full 2 volts, you will see the output voltage slowly drop down.

I pulled out a 7809 and hooked it up to my variable power supply, and found that this was mostly true; the dropout voltage was about 1.2 volts (two diode drops). That means I would expect that the 7812 would put out less voltage but something close to 12V.

So, that suggests that we have two issues going on; we don’t have enough voltage coming in for the regulator to work and the regulator looks fried. That is supported by some data I had before this where the game was acting very weird and the voltage at TP3 was fluctuating all over the place. So, a new 7812, and it would be a good idea to replace the 1n4004 diodes and the electrolytic capacitors in this section at the same time, since this board is nearly 25 years old.

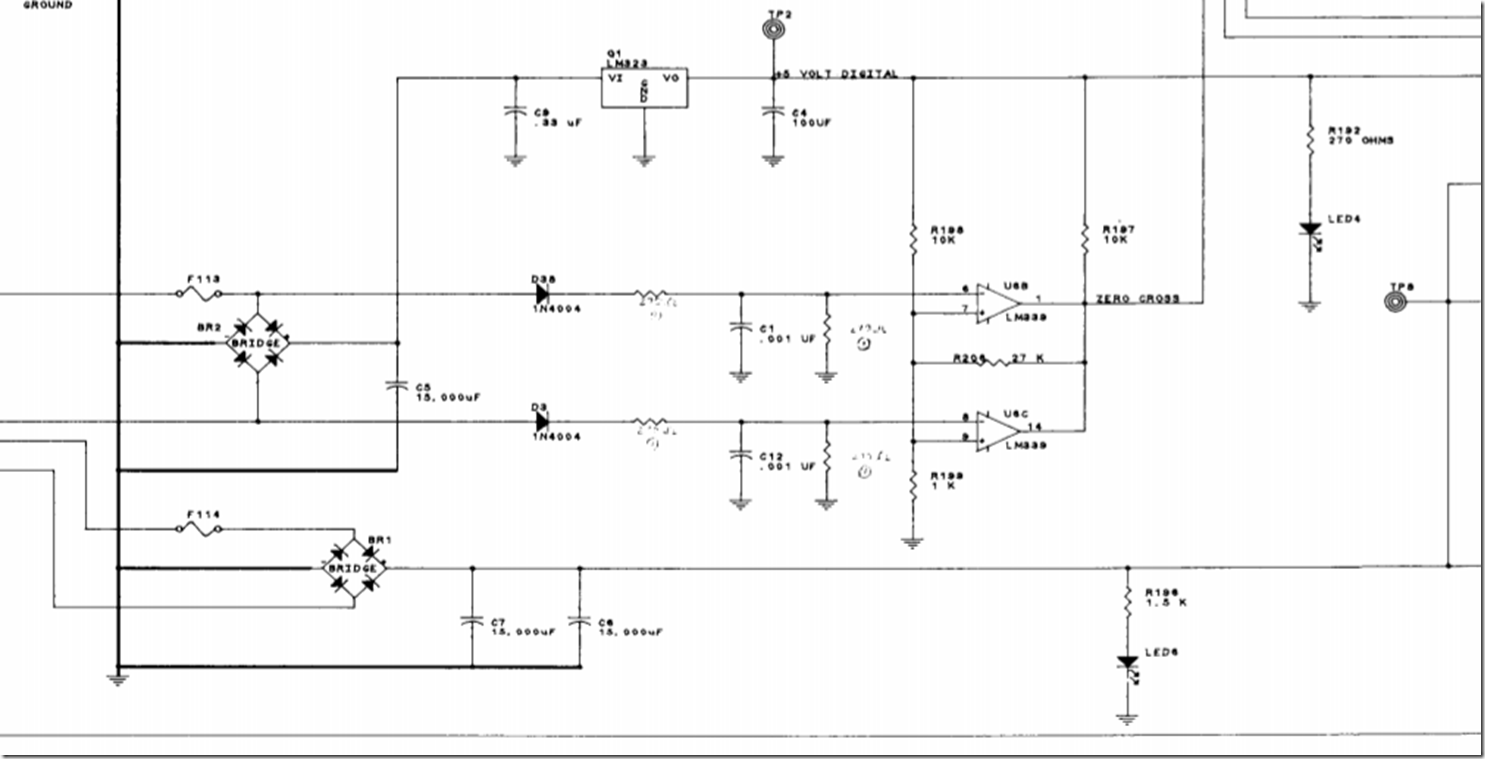

Looking at the input voltages at T8, note that there is a decent AC component in the DC voltage – about 0.8 volts. Back to the schematics:

This is also really simple; we have AC from the transformer coming in, going through a full-wave rectifier, and then there are two honking big 15,000 uF electrolytic capacitors. As these capacitors age, they are going to lose some capacity and have an increased internal resistance; both of those make them worse at filtering, so it’s time to replace those as well. It’s possible that the AC that they are putting out ended up hastening the end of the 7812.

It’s typical to replace both the capacitors and the bridges when the board is reworked, just to make sure, so I will probably do that.

I am a little concerned by some of the values I see on my TZ board; there are some indications that the caps there need replacement as well. I’ll do the WCS and then compare it to the TZ one.