Back in May of 2017, I started a journey to learn more about how the biochemistry of weight works; how our bodies metabolism carbohydrates, protein, and fats, and how that influences our weight.

When I started, I had a pretty simplistic view of how our bodies work. I’m still only starting to have a functional understanding of the underlying biochemistry, but what I’ve found is that our bodies are very complex and fascinating systems shaped by the environment in which we evolved, and that if you understand the underlying biochemistry, things make more sense.

So… This is my attempt to present a simplified view of the underlying biochemistry. If you want to learn more, I recommend starting with a copy of “Mark’s Basic Medical Biochemistry”, but I’ll caution you that the section on carbohydrate metabolism alone is around 84 pages, so it’s pretty dense. If you want a slightly lighter approach, you can try “Mark’s Essentials of Medical Biochemistry”, which is a bit shorter. In either case, read them and then find some YouTube videos that talk about the subject, and iterate on this process a few times.

A few basic principles:

Our bodies are adaptive systems

If you’ve ever trained for an athletic event, you know that when you start training it’s really hard, but it gets easier over time as your body adapts, by making physical changes to your body. Our bodies also have an adaptive response to the kinds of foods that we eat, and that response can take time.

Our bodies try to be energy efficient

We evolved in an environment where food was not always plentiful, and our bodies generally attempt to be efficient and not waste any food calories.

Reactions to diets vary significantly between individuals

Genetics, age, sex, medical history, and activity level are all significant when considering how a specific person reacts to a specific diet. Or, to put it another way, one person may be able to remain healthy on a diet that would make somebody else very sick.

Carbs

I’m starting with carbs because their role is central to how your body reacts to the food that you eat. I’m going to talk about the different kinds of carbohydrates, how they are digested/absorbed, and how they are metabolized (used) by our bodies.

The nomenclature around carbs is a bit confusing, but they break into four broad classes:

Simple Sugars (aka “monosaccharides”)

The simple sugars are the ones that aren’t broken down by our digestive systems to something simpler. Most people are familiar with fructose and glucose, and there is also galactose, which I’ll discuss more in a bit. There are also some rarer sugars and sugar alcohols that I’m ignoring for now.

Compound Sugars (aka “Disaccharides”)

“Di” meaning “two”, these are sugars that are compounds of two simple sugars.

Sucrose (aka “table sugar”) is a compound of one molecule of glucose and one molecule of fructose

Lactose (aka “milk sugar”) is a compound of one molecule of glucose and one molecule of galactose

Maltose (aka “malt sugar”) is a compound of two molecules of glucose.

The much maligned High Fructose Corn Syrup is not a compound sugar, but a mixture of simple sugars. It comes in different fructose/glucose ratios, with the most common one being 55% fructose, so it’s similar to sucrose in its underlying composition and effect on the body.

Complex carbohydrates (aka “Oligosaccharides” and “Polysaccharides”)

All of the complex carbohydrates are chains of simple sugars hooked together (“oligo” means “a few”, and “poly” means “a lot”).

In this class we have ingredients like maltodextrin (a small chain of glucose molecules), or starches (big chains of glucose molecules).

Cooked starches are easily broken down into their simple sugars by our digestion. Some raw starches – also known as “resistant starches” – are poorly digested in the small intestine, and digested by bacteria in the large intestine and converted to short-chain fatty acids, which are absorbed. I would call them “starches that don’t act like more familiar starches”.

Undigestible carbohydrates (aka “fiber”)

Humans don’t have the digestive equipment to extract energy from carbohydrates like cellulose, so they just pass through our systems.

Carbohydrate absorption

With the exception of resistant starches and fiber, all of the carbohydrates are broken down to glucose, fructose, or galactose by the digestive system before they enter the bloodstream. The rate at which they enter the bloodstream depends upon a number of factors. A refined sugar is more accessible than one that is bound up within fiber in a food, so it is absorbed faster. A sugar that is by itself is more accessible than one that is mixed in with fat and protein. Different sugars have different transport mechanisms to get them from the digestive system into the blood stream and therefore have different rates of absorption.

But at the bottom, it’s glucose, fructose, or galactose. The sugars that you get from eating an apple aren’t chemically any different from those you get from a can of Coke. The two foods – if you can call a can of coke “food” – differ in the total amount of carbs, the ratios of different types of carbs, the rate at which the carbs are absorbed, and the non-sugar ingredients, but they both end up as simple sugars in your system.

Complex carbohydrates also aren’t inherently different than simple sugars; they may not taste sweet, but they end up as simple sugars (typically glucose) when they are absorbed.

Carbohydrate Metabolism

Metabolism is all about what happens to the nutrient after it gets into our bloodstream. It turns out that the different simple sugars are processed very differently.

I’m going to start with glucose metabolism.

Glucose metabolism

The amount of glucose in our blood – our blood glucose (or blood sugar) level – is one of the most important values for us as living organisms. Too little (aka “hypoglycemia”), and we get hungry, headachy, sleepy, confused, or worse. Too much (aka “hyperglycemia”), and we have other issues; a lot of our body’s systems do not work well with too little or too much blood glucose.

Our bodies therefore have a system to keep blood sugar constant, and this is a high priority system; it is fair to say that “keep blood glucose within range” is Job One for our regulatory systems.

Let’s say we ate a small plain bagel or drank a can of Coke. That’s going to send somewhere around 30 grams of glucose into our system. That is over 7 times the amount of glucose we normally have in our bloodstream, so we need a place to put the excess glucose, and biochemical system to pull the glucose out of the blood and put it in that storage place.

Storing Glucose

There are two different methods of storing glucose in our bodies.

We can store it in our liver or our muscles as glycogen, a compound that is very close to glucose chemically. Glycogen is a little like a starch; it’s just a bunch of glucose molecules surrounding a protein known as glycogenin, and it’s quick and easy to get the glucose back out. The storage for glycogen is fairly limited; the muscles can store about 400 grams, and the liver can store about 100 grams, or 500 grams / 2000 calories total. If you have ever “hit the wall” or “bonked” during extended exercise, you’ve experienced what happens when you run out of liver glycogen.

If your liver and muscle glycogen stores are already full, the excess glucose out of the blood needs to go somewhere else.

There is only one other place for storing the excess energy that the glucose represents, and that is our fat stores. We tend to think of sugars and fats to be very different things – one is white and crystalline, and the other is oily or greasy – but they are both molecules made from carbon, oxygen, and hydrogen. The liver and fat cells can take in the excess glucose and convert it to fat, which is stored in our fat cells.

The biochemistry to do this is built on a hormone that we have all heard of, insulin. When blood sugar is high, the pancreas releases insulin, which has 3 main effects our system:

- The muscles and liver increase their absorption of glucose to store as glycogen (assuming there is room to store it).

- The body turns off fat burning, so that current energy use will help use up glucose.

- The fat cells increase their absorption of glucose to store as fat.

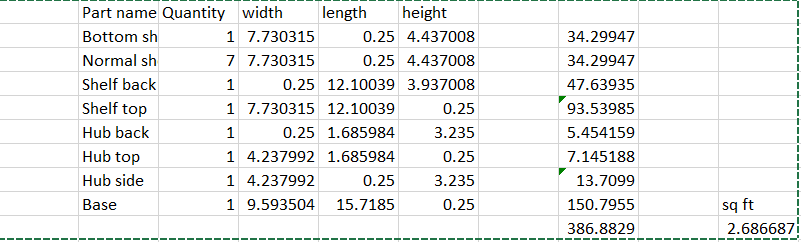

The speed at which glucose can be stored depends on where it is being stored; storing it as glycogen is quick, while storing it as fat is slow. Here’s an interesting chart from a study:

The subjects in this study had slept overnight, which had burned some of the glycogen in their stores. They then gave them one of three breakfasts:

- A can of Coke

- A service of instant oatmeal

- 2 poached eggs.

Both the Coke and the oatmeal have a lot of carbs, and the eggs have almost none.

Then, they fed them a *second* breakfast of oatmeal – a lot of carbs – and measured their blood sugar over time.

What they found was that if the first breakfast was eggs, the second breakfast had little effect on their blood glucose, because all of those carbs went straight back into filling up the glycogen stores. If the first breakfast had carbs, they had mostly refilled the glycogen stores already, and it therefore took quite a while to get the blood sugar back to normal. Which means that much of the second breakfast was stored as fat.

These charts showed what happened with a healthy person – one that we would call “insulin sensitive”. The blood glucose gets back to normal.

For some people, that doesn’t happen. There are different theories as to why it doesn’t happen; one is that the glycogen stores just get full, one is that the fat and liver cells can’t do the conversion to fat well, and there are others. Regardless, their glucose-absorbing cells become resistant to the effects of insulin, which we call “insulin resistance”. The first reaction of our bodies is to try harder by using more insulin, but this is an arms race that can eventually lead to problems in insulin production. Many people progress from insulin resistance to type II diabetes and metabolic syndrome.

I want to stress here that insulin resistance and type II diabetes are about the abilities of our bodies to regulate blood glucose levels, they are not about weight. It is true that people who carry a lot of extra weight are more likely to have blood glucose issues, but there are obese people who have good blood glucose control, and – perhaps more surprisingly – there are thin or normal weight people who have insulin or type II diabetes. They have bodies that are not good at converting excess glucose to fat.

That is why testing for blood glucose over time is important. Unfortunately, testing for blood glucose every day is intrusive and not something you can use with the general population, so for a long time all that was used was the blood glucose measured at one time, which is not a good predictor.

Then a weird bit of biochemistry came to the rescue. It turns out that in our red blood cells, the hemoglobin that transports oxygen can become glycated – it can have a glucose molecule attached to it. The chance of that happening depends on the average amount of glucose in the blood; if you have a low average blood glucose, few of your hemoglobin molecules will be glycated, while if you have high average glucose, more will be glycated.

And, it turns out that when red blood cells die, we can look at the hemoglobin and see how much was glycated, and therefore have a good idea the overall glucose levels, as a weighted average for the past few months.

The test to do this generates a value known as HbA1c, or simply A1c, and it’s the prime diagnostic measure for insulin resistance and type II diabetes.

Low blood glucose

Thankfully, this is a lot simpler.

The reaction to low blood glucose is somewhat the opposite to high blood glucose. It is mediated by a hormone released by the pancreas known as glucagon, which has roughly the opposite effects as insulin:

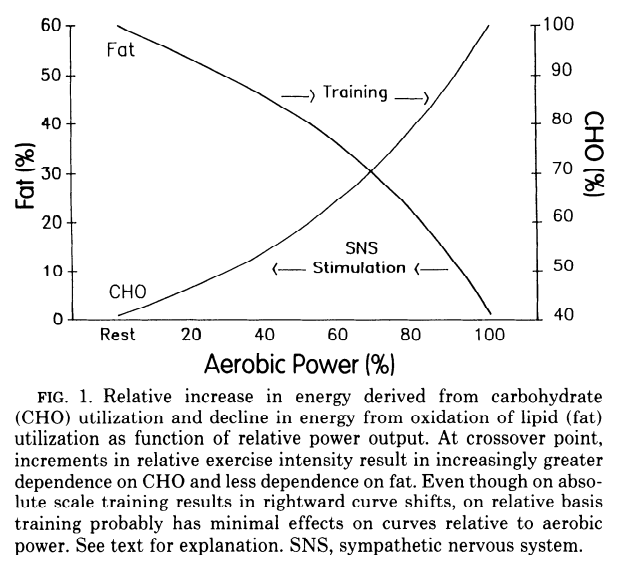

The glycogen stored in the liver is converted back into glucose and released into the bloodstream (the glycogen in muscles can only be used locally; it cannot be released back into the bloodstream).

The body encourages the release and burning of fatty acids rather than carbohydrates.

If that is enough to raise the blood glucose, that everybody is happy. If the low blood glucose continues for longer – say for a few days – the body switches over to an alternate fueling approach known as “ketosis”, which involves the following changes:

The liver starts producing what are known as “ketone bodies”, which you can think of a glucose substitute for some of the body tissues; the brain can largely use ketone bodies for fuel, as can some muscles.

The muscle switch to burning more fat and less carbohydrate to produce energy. Like any exercise adaptation, this occurs over time.

The liver starts producing glucose from whatever it has lying around; it might be glycerol from fat metabolism or excess protein, or both. This is known as “gluconeogenesis”.

Together the switch to ketone bodies and the creation of new glucose is enough for the body to function normally without eating carbs. Adapting to this takes a couple of weeks for most individuals, though adapting to burn more fat during exercise takes much longer.

Ketosis is a response whenever carbs are severely limited, whether it be a fast or a ketogenic diet. Ketosis is not an all-or-nothing response; a person on a relatively low-carb diet might be in ketosis overnight when their carb reserves get low and then switch out of it during the day when carbs are more available.

And that is the story on glucose.

Galactose metabolism

Galactose metabolism is pretty much like glucose metabolism, except a trip to the liver is required to break the galactose molecule apart into two glucose molecules, which are either used by the liver or released into the bloodstream.

Fructose metabolism

Our body cannot metabolize fructose directly, so first it has to take a trip to the liver to be converted to something that is more useful.

It ends up as one of three things:

Glucose, which is stored in the liver, converted to fat by the liver, or released into the blood stream.

Lactate, which can be used by other tissues

Triglycerides (ie fat).

There is considerable discussion around what the proportions are between those three products and what controls those proportions.

Some researchers theorize that in some cases, the triglyceride pathway is especially active and that leads to the accumulation of fat in the liver and a condition known as Non Alcoholic Fatty Liver Disease (NAFLD). My limited understanding says that we don’t have definitive evidence on this, but we do know that alcohol is metabolized into fat in the liver and the accumulation of fat causes alcoholic fatty liver disease, and since fructose can also be metabolized into fat in the liver, it’s an interesting hypothesis.

Futures

That’s all for carbohydrates.

Upcoming, we have fat and protein to talk about, and probably a discussion around energy partitioning, which is how our bodies decide what fuel to burn.